Description

Measurement Accuracy

| Voltage DC | Range/Resolution | 1 Year | 2 Years | ||

| 100.000 mV | 0.02% + 0.005 mV | 0.03% + 0.005 mV | |||

| 3.00000 V | 0.02% + 0.00005 V | 0.03% + 0.00005 V | |||

| 30.0000 V | 0.02% + 0.0005 V | 0.03% + 0.0005 V | |||

| 300.00 V | 0.05% + 0.05 V | 0.07% + 0.05 V | |||

| Voltage AC | 3.000 V (40 Hz to 500 Hz) / 0.001 V | 0.5% + 0.002 V | 1.0% + 0.004 V | ||

| 30.00 V (40 Hz to 500 Hz) / 0.01 V | 0.5% + 0.02 V | 1.0% + 0.04 V | |||

| 300.0 V (40 Hz to 500 Hz) / 0.1 V | 0.5% + 0.2 V | 1.0% + 0.2 V | |||

| Current DC | 30.000 mA | 0.01% + 5 uA | 0.015% + 7 uA | ||

| 110.00 mA | 0.01% + 20 uA | 0.015% + 30 uA | |||

| Resistance | 10.000 Ω | 0.05% + 50 mΩ | 0.07% + 70 mΩ | ||

| 100.00 Ω | 0.05% + 50 mΩ | 0.07% + 70 mΩ | |||

| 1.0000 kΩ | 0.05% + 500 mΩ | 0.07% + 0.5 Ω | |||

| 10.000 kΩ | 0.1% + 10 Ω | 0.15% + 15 Ω | |||

| Frequency | 1.00 to 110.00 Hz / 0.01 Hz | 0.05 Hz | |||

| 110.1 to 1100.0 Hz / 0.1 Hz | 0.5 Hz | ||||

| 1.101 to 11.000 kHz / 0.001 kHz | 0.005 kHz | ||||

| 11.01 to 50.00 kHz / 0.01 kHz | 0.05 kHz | ||||

Source Accuracy

| 1 Year | 2 Years | ||||

| Voltage DC | 100.000 mV | 0.01% + 0.005 mV | 0.015% + 0.005 mV | ||

| 1.00000 V | 0.01% + 0.00005 V | 0.015% + 0.0005 V | |||

| 15.0000 V | 0.01% + 0.0005 V | 0.015% + 0.0005 V | |||

| Current DC | 22.000 mA (source) | 0.01% + 0.003 mA | 0.02% + 0.003 mA | ||

| Current sink (simulate) | 0.02% + 0.007 mA | 0.04% + 0.007 mA | |||

| Resistance | 10.000 Ω | 0.01% + 10 mΩ | 0.015% + 15 mΩ | ||

| 100.00 Ω | 0.01% + 20 mΩ | 0.015% + 30 mΩ | |||

| 1.0000 kΩ | 0.02% + 0.2 Ω | 0.03% + 0.3 Ω | |||

| 10.000 kΩ | 0.02% + 3 Ω | 0.03% + 5 Ω | |||

| Frequency | 0.1 to 10.99 Hz | 0.01 Hz | |||

| 0.01 to 10.99 Hz | 0.01 Hz | ||||

| 11.00 to 109.99 Hz | 0.1 Hz | ||||

| 110.0 to 1099.9 Hz | 0.1 Hz | ||||

| 1.100 to 21.999 kHz | 0.002 kHz | ||||

| 22.000 to 50.000 kHz | 0.005 kHz | ||||

Technical

| Data log functions | Measure functions | Voltage, current, resistance, frequency, temperature, pressure | |||

| Reading rate | 1, 2, 5, 10, 20, 30, or 60 readings/minute | ||||

| Maximum record length | 8000 readings (7980 for 30 or 60 readings/minute) | ||||

| Ramp functions | Source functions | Voltage, current, resistance, frequency, temperature | |||

| Rate | 4 steps/second | ||||

| Trip detect | Continuity or voltage (continuity detection not available when sourcing current) | ||||

| Loop power function | Voltage | Selectable, 26 V | |||

| Accuracy | 10%, 18 V minimum at 22 mA | ||||

| Maximum current | 25 mA, short circuit protected | ||||

| Maximum input voltage | 50 V DC | ||||

| Step functions | Source functions | Voltage, current, resistance, frequency, temperature | |||

| Manual step | Selectable step, change with arrow buttons | ||||

| Autostep | Fully programmable for function, start delay, stepvalue, time per step, repeat | ||||

| Environmental Specifications | |||||

| Operating temperature | -10°C to +50°C | ||||

| Storage temperature | -20°C to +60°C | ||||

| Dust/water resistance | Meets IP52, IEC 529 | ||||

| Operating altitude | 3000 m above mean sea level (9842 ft) | ||||

| Safety Specifications | |||||

| Agency approvals | CAN/CSA C22.2 No 1010.1-92, ASNI/ISA S82.01-1994, UL3111, and EN610-1:1993 | ||||

| Mechanical and General Specifications | |||||

| Size | 136 x 245 x 63 mm (5.4 x 9.6 x 2.5 in) | ||||

| Weight | 1.2 kg (2.7 lb) | ||||

| Batteries | Internal Battery Pack Li-ion: 7.2V,4400mAh, 30 Wh | ||||

| Battery life | >8 hours typical | ||||

| Battery replacement | Replace without opening calibrator; no tools required | ||||

| Side port connections | Pressure module connector | ||||

| USB Connector to interface to your PC | |||||

| Digital instrument (HART) connector | |||||

| Connection for optional battery charger/eliminator | |||||

| Data storage capacity | 1 week of calibration procedures results | ||||

| 90 day specifications | The standard specification interval for the 750 Seriesare 1 and 2 years. | ||||

| Typical 90 day measurement and source accuracy can be estimated by dividing the one year "% of reading" or "% of output" specifications by 2. | |||||

| Floor specifications, expressed as "% of full scale" or "counts" or "ohms" remain constant. | |||||

Temperature, Resistance Temperature Detectors

| Degrees or % of reading - Type (α) | Range °C | Measure °C1 | |||

| 1 year | 2 year | ||||

| 100 Ω Pt (385) | -200 to 100 100 to 800 | 0.07°C 0.02% + 0.05°C | 0.14°C 0.04% + 0.10°C | ||

| 200 Ω Pt (385) | -200 to 100 100 to 630 | 0.07°C 0.02% + 0.05°C | 0.14°C 0.04% + 0.10°C | ||

| 500 Ω Pt (385) | -200 to 100 100 to 630 | 0.07°C 0.02% + 0.05°C | 0.14°C 0.04% + 0.10°C | ||

| 1000 Ω Pt (385) | -200 to 100 100 to 630 | 0.07°C 0.02% + 0.05°C | 0.14°C 0.04% + 0.10°C | ||

| 100 Ω Pt (3916) | -200 to 100 100 to 630 | 0.07°C 0.02% + 0.05°C | 0.14°C 0.04% + 0.10°C | ||

| 100 Ω Pt (3926) | -200 to 100 100 to 630 | 0.08°C 0.02% + 0.06°C | 0.16°C 0.04% + 0.12°C | ||

| 10 Ω Cu (427) | -100 to 260 | 0.2°C | 0.4°C | ||

| 120 Ω Ni (672) | -80 to 260 | 0.1°C | 0.2°C | ||

| Source current | Source °C | Allowable current2 | |||

| 1 year | 2 year | ||||

| 1 mA | 0.05°C 0.0125% + 0.04°C | 0.10°C 0.025% + 0.08°C | 0.1 mA to 10 mA | ||

| 500 μA | 0.06°C 0.017% + 0.05°C | 0.12°C 0.034% + 0.10°C | 0.1 mA to 1 mA | ||

| 250 μA | 0.06°C 0.017% + 0.05°C | 0.12°C 0.034% + 0.10°C | 0.1 mA to 1 mA | ||

| 150 μA | 0.06 C 0.017% + 0.05°C | 0.12 C 0.034% + 0.10°C | 0.1 mA to 1 mA | ||

| 1 mA | 0.05°C 0.0125% + 0.04°C | 0.10°C 0.025% + 0.08°C | 0.1 mA to 10 mA | ||

| 1 mA | 0.05°C 0.0125% + 0.04°C | 0.10°C 0.025% + 0.08°C | 0.1 mA to 10 mA | ||

| 3 mA | 0.2°C | 0.4°C | 0.1 mA to 10 mA | ||

| 1 mA | 0.04°C | 0.08°C | 0.1 mA to 10 mA | ||

| 1. For two and three-wire RTD measurements, add 0.4°C to the specifications. 2. Supports pulsed transmitters and PLCs with pulse times as short as 1 ms | |||||

Temperature, Thermocouples

| Type | Source °C | Measure °C | Source °C | ||

| 1 year | 2 years | 1 year | 2 years | ||

| E | -250 to -200 | 1.3 | 2.0 | 0.6 | 0.9 |

| -200 to -100 | 0.5 | 0.8 | 0.3 | 0.4 | |

| -100 to 600 | 0.3 | 0.4 | 0.3 | 0.4 | |

| 600 to 1000 | 0.4 | 0.6 | 0.2 | 0.3 | |

| N | -200 to -100 | 1.0 | 1.5 | 0.6 | 0.9 |

| -100 to 900 | 0.5 | 0.8 | 0.5 | 0.8 | |

| 900 to 1300 | 0.6 | 0.9 | 0.3 | 0.4 | |

| J | -210 to -100 | 0.6 | 0.9 | 0.3 | 0.4 |

| -100 to 800 | 0.3 | 0.4 | 0.2 | 0.3 | |

| 800 to 1200 | 0.5 | 0.8 | 0.3 | 0.3 | |

| K | -200 to -100 | 0.7 | 1.0 | 0.4 | 0.6 |

| -100 to 400 | 0.3 | 0.4 | 0.3 | 0.4 | |

| 400 to 1200 | 0.5 | 0.8 | 0.3 | 0.4 | |

| 1200 to 1372 | 0.7 | 1.0 | 0.3 | 0.4 | |

| T | -250 to -200 | 1.7 | 2.5 | 0.9 | 1.4 |

| -200 to 0 | 0.6 | 0.9 | 0.4 | 0.6 | |

| 0 to 400 | 0.3 | 0.4 | 0.3 | 0.4 | |

| B | 600 to 800 | 1.3 | 2.0 | 1.0 | 1.5 |

| 800 to 1000 | 1.0 | 1.5 | 0.8 | 1.2 | |

| 1000 to 1820 | 0.9 | 1.3 | 0.8 | 1.2 | |

| R | -20 to 0 | 2.3 | 2.8 | 1.2 | 1.8 |

| 0 to 100 | 1.5 | 2.2 | 1.1 | 1.7 | |

| 100 to 1767 | 1.0 | 1.5 | 0.9 | 1.4 | |

| S | -20 to 0 | 2.3 | 2.8 | 1.2 | 1.8 |

| 0 to 200 | 1.5 | 2.1 | 1.1 | 1.7 | |

| 200 to 1400 | 0.9 | 1.4 | 0.9 | 1.4 | |

| 1400 to 1767 | 1.1 | 1.7 | 1.0 | 1.5 | |

| C | 0 to 800 | 0.6 | 0.9 | 0.6 | 0.9 |

| 800 to 1200 | 0.8 | 1.2 | 0.7 | 1.0 | |

| 1200 to 1800 | 1.1 | 1.6 | 0.9 | 1.4 | |

| 1800 to 2316 | 2.0 | 3.0 | 1.3 | 2.0 | |

| L | -200 to -100 | 0.6 | 0.9 | 0.3 | 0.4 |

| -100 to 800 | 0.3 | 0.4 | 0.2 | 0.3 | |

| 800 to 900 | 0.5 | 0.8 | 0.2 | 0.3 | |

| U | -200 to 0 | 0.6 | 0.9 | 0.4 | 0.6 |

| 0 to 600 | 0.3 | 0.4 | 0.3 | 0.4 | |

| BP | 0 to 1000 | 1.0 | 1.5 | 0.4 | 0.6 |

| 1000 to 2000 | 1.6 | 2.4 | 0.6 | 0.9 | |

| 2000 to 2500 | 2.0 | 3.0 | 0.8 | 1.2 | |

| XK | -200 to 300 | 0.2 | 0.3 | 0.2 | 0.5 |

| 300 to 800 | 0.4 | 0.6 | 0.3 | 0.6 | |

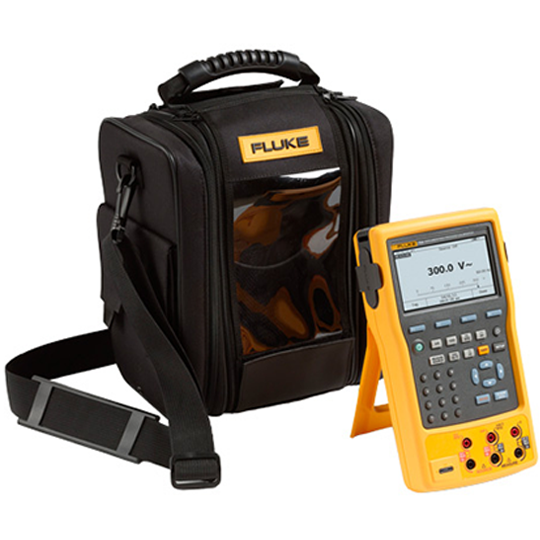

Work smarter. Work faster.

The 754 is a power multifunction documenting calibrator that lets you download procedures, lists, and instructions created with software-or upload data for printing, archiving, and analysis. The 754 also features a powerful built in HART® interface capable of performing nearly all the day-to-day tasks you now perform with a separate communicator.

- Measure volts, mA, RTDs, thermocouples, frequency, and ohms to test sensors, transmitters and other instruments

- Source/simulate volts, mA, thermocouples, RTDs, frequency, ohms, and pressure to calibrate transmitters

- Power transmitters during test using loop supply with simultaneous mA measurement

- Measure/source pressure using any of 29 Fluke 700Pxx Pressure Modules

- Create and run automated as-found/as-left procedures to satisfy quality programs or regulations. Record and document results

- Holds up to a full week of downloaded procedures and calibration results.

- Use many features like autostep, custom units, user entered values during test, one-point and two-point switch testing, square root DP flow testing, programmable measurement delay etc.

- Easy to use

- Three year warranty

- Bright white dual display. Read both sourced and measured parameters simultaneously.

- Multi lingual interface

- Rechargeable Li-Ion battery for 10 hour uninterrupted use. Includes gas gauge.

- Handling of fast pulsed RTD transmitters and PLCs, with pulses as short as 1 ms.

- Delivered with DPC/Track Sample software.

- Compatible with many Asset Management software packages.

HART Capabilities

The 754 is designed to take on nearly all the day-to-day tasks you now perform with a separate communicator. In fact, it offers the communication capabilities of the 375 HART communicator.

- Requires no external box or second tool for everyday HART calibration and maintenance.

- Offers fast HART communication.

- Supports popular models of HART transmitters, with more devise-specific command support than any other HART field calibrator.

- Works with multiple masters, burst mode, and multi-drop configurations.

- Is easy to update as additional instruments are added and new HART versions are released.

- Interrogate to determine device type, manufacturer, model, tag.

- Reconfigure the sensor mapping of dual sensor temperature transmitters.

- Read HART PV function and smart transmitter digital output while measuring analog mA output.

- Read and write HART configuration functions to make field adjustments to PV range points, damping, and other top-level configuration settings.

- Re-label smart transmitters by reading and writing to the HART tag field.

Versatile HART Protocol support

| Manufacturer | Pressure instruments | Temperature instruments | Coriolis instruments |

| ABB/Kent-Taylor | 600T | 658T1 | |

| ABB/Hartmann & Braun | Contrans P1, AS 800 Series | ||

| Endress & Hauser | CERABAR S, CERABAR M, DELTABAR S | TMT 1221,TMT 1821, TMT 1621 | |

| Foxboro Eckardt | TI/RTT201 | ||

| Foxboro/Invensys | I/A Pressure | ||

| Fuji | FCX FCXAZ | FRC | |

| Honeywell | ST3000 | STT25T1, STT25H1 | |

| Micro Motion | 2000 2000 IS 9701 9712 9739 | ||

| Moore Products | 3441 | ||

| Rosemount | 1151 2088 3001C 3051, 3051S | 3044C 644 3144 3244, 3144P | |

| Siemens | SITRANS P DS SITRANS P ES | ||

| SMAR | LD301 | TT3011 | |

| Viatran | I/A Pressure | ||

| Wika | UNITRANS | T32H1 | |

| Yokogawa | EJA | YTA 110, 310 and 320 |

1Sensor Trim not supported

The 754 supports the commands contained in HART protocol Version 5.7. With 2 MB of memory, the 754 supports a substantial set of HART instructions:

- Universal commands provide functions that are implemented in all field devices, for example, read manufacturer and device type, read primary variable (PV), or read current output and percent of span.

- Common practice commands provide functions that are common to many but not all field devices, for example read multiple variables, set damping time, or perform loop test.

- Device-specific commands provide functions that are unique to a particular field device, for example sensor trim.

HART Operating Modes Supported

- Point to Point operation , the most commonly used mode, connects the 754 to a single HART device in a 4-20 mA loop.

- In Multi-Drop mode , several HART instruments can be bussed together. The 754 searches for each, identifies addresses in use, and allows you to select the instrument for calibration and related operations.

- In Burst Mode, the HART instrument transmits bursts of data without waiting to be interrogated by a master unit. The 754 can take transmitters out of burst mode during test or calibration, then later restore them to burst mode.

Pressure Modules

Covers virtually any pressure application including gauge, differential, dual (compound), absolute, and vacuum.

- Display pressure readings in any of 10 different pressure units you specify in the calibrator setup.

- Rugged urethane molded cases protect the modules from rough handling and harsh conditions.

- Features internal temperature compensation from 0° to 50°C for full accuracy performance.

- Includes NIST-traceable calibration certificate.

- Modules can be calibrated locally, helping to control costs.

A family of 29 optional pressure modules provides pressure calibration and measurement capabilities. Twenty-eight modules are available, with basic accuracy specs to 0.05%. Ranges start at 0 – 1 inH20 (0 – .25kPa) and go to 0 – 10,000 psi (0 – 70,000 kPa). Additional information about pressure modules is available on the Pressure Modules Home Page.

Automated Procedures

Allow you to quickly set up powerful, automated calibration procedures for linear transmitters, DP flow transmitters, and one- and two-point limit switches. Simply select the appropriate measure and/or source functions and fill out the procedure template. The 750 Series does the rest. It quickly performs the test, calculates the errors, and displays the final results, highlighting out of tolerance points.

Custom Units

Enable you to map one unit to another, such as mV to °C or °F. Allows you to use the Fluke 750 Series with millivolt output accessories such as the Fluke 80T-IR Temperature Probe, and to document tests using non-supported units such as parts per million or revolutions per minute.

User-entered Values

Enables technicians to record calibration results that were sourced and/or measured by other devices such as panel meters or readout-only devices.

Limit Switch Calibration

Procedures perform fast, automated calibration of one and two-point limit switches for voltage, current, temperature, and pressure.

Differential Pressure Flow Instrument Calibration

Routines use a square root function to directly calibrate DP flow instruments.

Additional Features

Multifunctional

Calibrate temperature, pressure, voltage, current, resistance, and frequency. Since it both measures and sources, you can troubleshoot and calibrate all with one rugged tool.

Powerful, yet easy to use

The easy-to-follow menu-driven display guides you through any task. Get up to speed in minutes, not days. Programmable calibration routines enable you to create and run automated as-found/as-left procedures to ensure fast, consistent, calibrations.

Records and documents results

To support your ISO-9000 or regulatory standards the Fluke 754 captures your calibration results, eliminating the need to juggle a pen and pad in the field. The USB interface lets you transfer the results to a PC, thus saving the time of having to manually transcribe them when you return to the shop.

Truly hand-held

Small enough to fit easily into a tool bag and to use in tight spaces. Runs an entire shift on a rechargeable Li-ion battery pack.

Rugged and reliable

Count on Fluke's rugged design to deliver top accuracy and reliability in harsh environments. Overmolded urethane case stands up to rough handling in industrial environments.

Bright white display

Lets you read your results in any kind of light. Backlight has three (3) settings.

Soft keys

Provide one-touch access to enhanced functions such as task lists, automated procedures, scaling, min/max, stepping and ramping, and review memory.

Three operating modes

Measure, Source, or simultaneous Measure/Source, - enable technicians to troubleshoot, calibrate, or maintain instrumentation with just one tool.

Multi-lingual interface

Displays instructions in English, French, German, Spanish, and Italian.

Built-in algebraic calculator

With four functions-plus square root-stores, recalls, and performs calculations required for setting up instruments or evaluating data in the field. Use it to set the source function to a calculated value. There's no need to carry a pencil and paper or a separate calculator.

Programmable measurement delay

Inside automated procedures permits calibrating instruments that respond slowly.